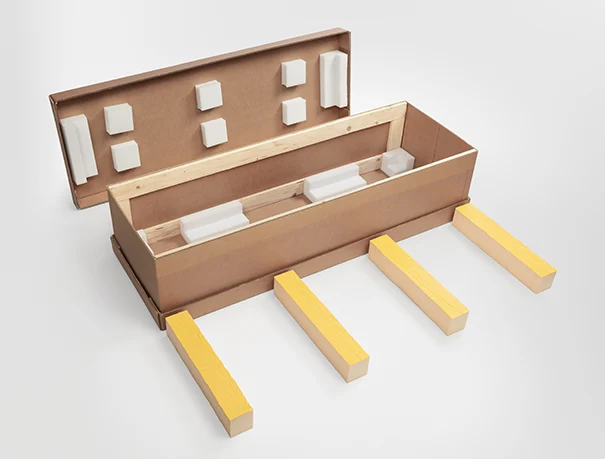

Multi-material packaging: wood, pressed cardboard and honeycomb

DESCRIPTION OF MULTI-MATERIAL PACKAGING

Multi material is any material that due to its special physical characteristics covers a specific need in the design of a protective packaging. They are usually elements that collaborate with traditional ams such as eps or expanded polyethylene foams.

The new logistics driven by e-commerce internet sales require packaging with special characteristics (customized packaging), which guarantee an optimal result. On their own, the many materials used in a multi-material solution are not effective; it is the combination of them that will give the expected result. Each multimaterial will provide a special feature.

Among the most usual elements to incorporate in a packaging are:

- Corner pieces to protect 2 and 3-sided corners.

- Flat blocks to spread over large surfaces.

- Long strips that when folded form an L-shape to protect side corners.

- Long strips that when folded form a U for lateral protection of flat surfaces.

BENEFITS OF MULTI-MATERIAL PACKAGING

The possibility of incorporating specific and customized elements in the packaging gives us the possibility to reinforce aspects that traditional packaging does not.

Wood can be used to stiffen weak points of the box or to distribute stresses on an impact-absorbing material.

Honeycomb is a versatile material, ideal for 100% paper solutions. Ideal for 100% paper solutions, with a wide variety of sizes, thicknesses, etc. There is the possibility of die-cutting shapes.

Shaped paper offers very high mechanical strength profiles for sharp impacts and helps in many cases to stiffen cardboard box structures.

PROPERTIES OF MULTI-MATERIAL PACKAGING

The already known properties of paper are joined in the case of packaging by the ease of disposing of the packaging in a responsible manner thanks to the widespread collection network for paper and cardboard.

OSB wood does not require phytosanitary treatments, which makes it ideal for export packaging.

Pressed paper elements are economical as they have been widely used for years in the reinforcement of palletized loads to give rigidity to the loaded pallet. Mandrels are also widely used, which makes them very economical. We generally use them cut to obtain short cylinders that are very resistant to compression lengthwise.

MULTI-MATERIAL PACKAGING APPLICATIONS

The main application of wood is to form or reinforce cardboard boxes, often double or triple cardboard for high resistance boxes for the transport of heavy equipment/material.

Honeycomb is mainly used as a support tray for more cushioning elements, usually as a base for packaging. It is often used with holes formed inside by die-cutting and pressing for centering of different objects.

The main application of pressed cardboard is the reinforcement of sharp edges of fragile materials such as wooden envelopes, cabinet edges, etc.

Do you want to know the price of this product?

WE MAKE RESISTANT PACKAGING

We reduce incident rates

We optimize packaging costs

SAVE UP TO

48%

IN ALL YOUR COSTS

If you are interested in improving your packaging system

CONTACT US WITHOUT COMMITMENT

Form Multi-material packaging: wood, pressed cardboard and honeycomb

Basic information on data protection

Responsible: BRAFIM MECPLAST, S.L.

Purposes : Manage the sending of information that you request. Sending commercial communications.

Legitimation: Consent. You can withdraw consent at any time.

Recipients: Your data will not be transferred to third parties except in case of legal obligation

Data subject's rights: To access, oppose, rectify and have their data deleted, as well as other rights as explained in the additional information.

You can access additional and extended information at this link.