Expanded polystyrene (EPS)

DESCRIPTION OF EXPANDED POLYSTYRENE

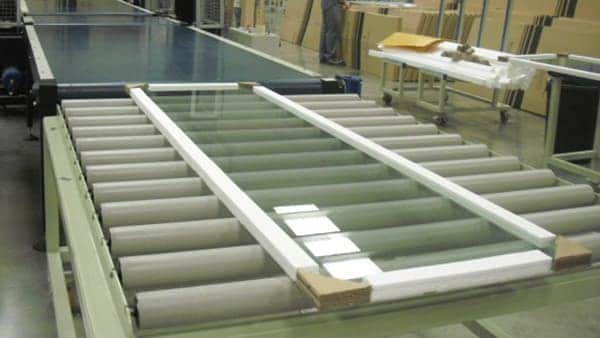

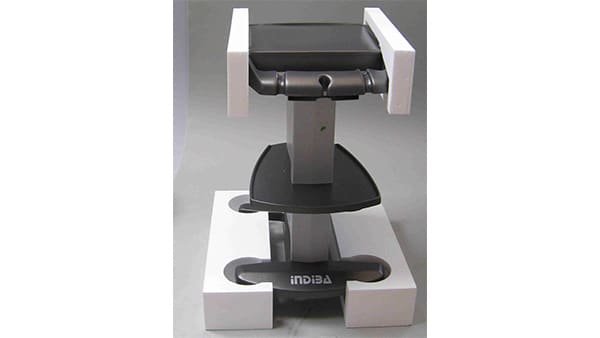

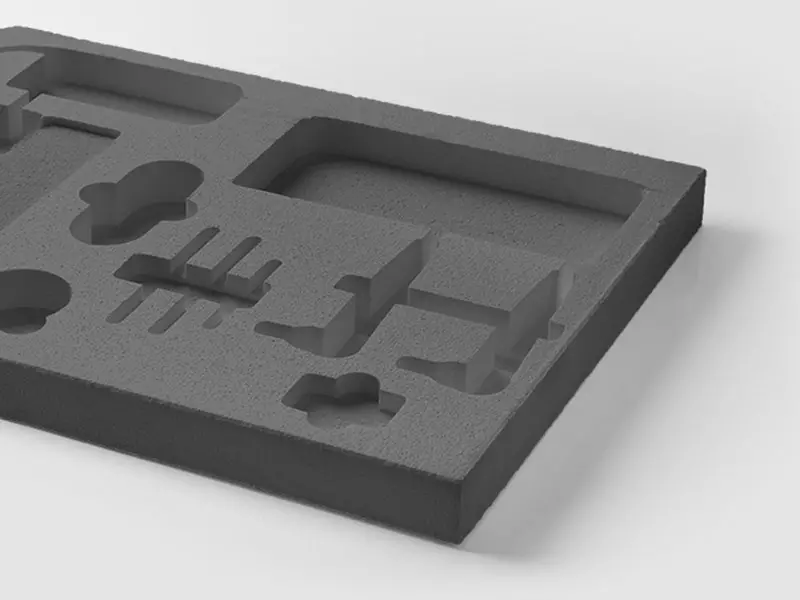

Protective elements machined in expanded polystyrene.

The mechanization allows to obtain protection elements of infinite possibilities and without the need of a mold. It is generally used the incandescent wire moved by cnc machines to obtain profiles and the machining by milling machines to obtain pieces or trays with custom-made cavities.

Expanded polystyrene is a foamed cellular plastic with a polystyrene base. This foam is semi-rigid, obtained through a polymerization process of monostyrene with the addition of pentane, obtaining a foamed material with millions of fine cells filled with air, almost 98% of the volume is air.

Normally, in the market, these foams can be seen in the form of blocks, sheets, machined or molded parts.

BENEFITS OF EXPANDED POLYSTYRENE

- The main benefit of expanded polystyrene is its unbeatable quality / price ratio. Expanded polystyrene is the shock absorption material with the best absorption/cost ratio.

- It is not multi impact although a good design will give it properties that would be maintained for a second and third impact.

- Expanded polystyrene is the easiest plastic material to recycle, with almost no energy consumption or waste, since it is suitable as raw material for the manufacture of new sheets by simply grinding it. The difficulty of recycling lies in the lack of collection points, infinitely less than paper or cardboard.

- Its ease of machining makes it ideal for both short and large series.

- Minimum response time from design to mass production.

PROPERTIES OF EXPANDED POLYSTYRENE

- Ease of cutting and molding.

- It is the most commonly used foam in protective packaging.

- Very good quality-price ratio.

- Good absorption of the first impact.

- Recyclable and excellent thermal insulator. Good compressive strength, ideal for making boxes and heavy equipment packaging from these expanded polystyrene blocks.

- Resistant to humidity.

- White color.

- Different densities for each type of resistance required.

EXPANDED POLYSTYRENE APPLICATIONS

In its more than 60 years of history, the EPS has been used in all types of packaging. We can affirm that there is no sector where a mechanized EPS solution has not been used.

From industry, to decoration, insulation, cold packing, etc.

Do you want to know the price of this product?

WE MAKE RESISTANT PACKAGING

We reduce incident rates

We optimize packaging costs

SAVE UP TO

48%

IN ALL YOUR COSTS

If you are interested in improving your packaging system

CONTACT US WITHOUT COMMITMENT

Form Expanded polystyrene (EPS)

Basic information on data protection

Responsible: BRAFIM MECPLAST, S.L.

Purposes : Manage the sending of information that you request. Sending commercial communications.

Legitimation: Consent. You can withdraw consent at any time.

Recipients: Your data will not be transferred to third parties except in case of legal obligation

Data subject's rights: To access, oppose, rectify and have their data deleted, as well as other rights as explained in the additional information.

You can access additional and extended information at this link.