Machined expanded polyethylene foam

DESCRIPTION OF MACHINED EXPANDED POLYETHYLENE FOAM

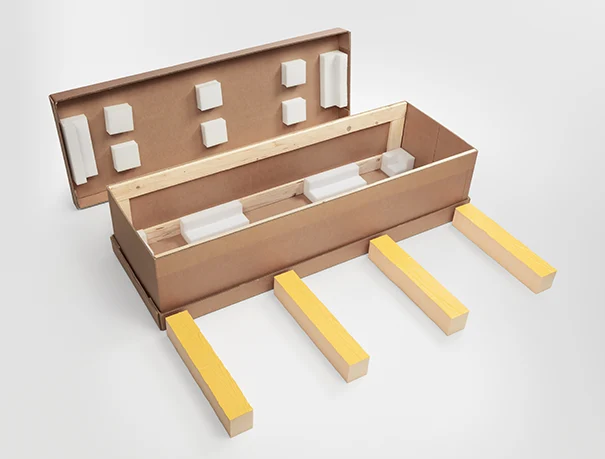

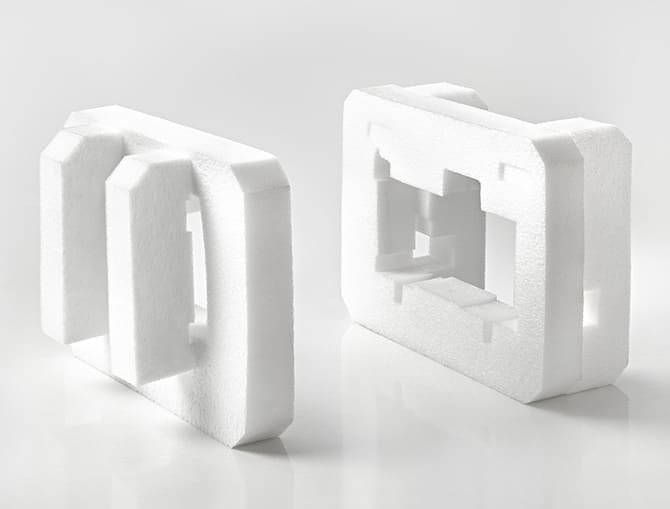

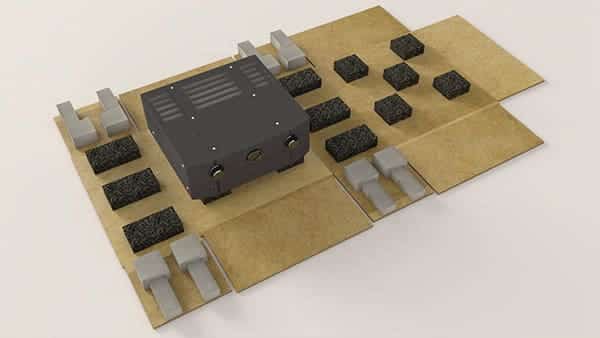

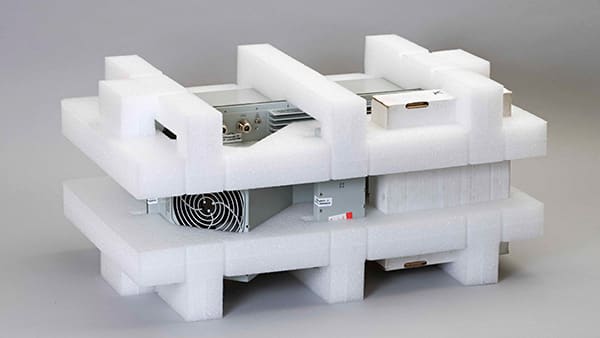

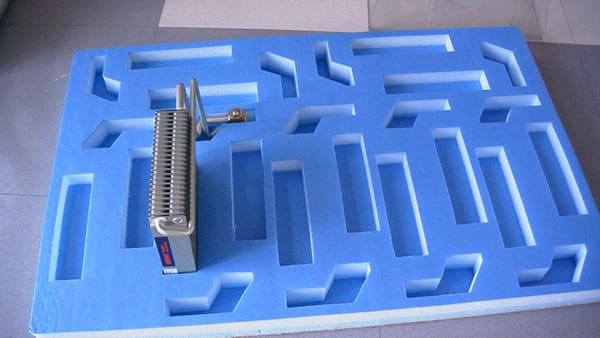

Machined elements in expanded polyethylene of high flexibility, from boards of different thicknesses it is possible to transform them into elements that cover the geometric needs that a customized protection element requires.

As it is a thermoplastic, it allows the joining of pieces together only by heat, which offers innumerable design possibilities.

It is mechanized with machines that can generate any shape without the need of molds.

Through CNC cutting with pressurized water, or blade, or abrasive wire. The most widespread is die-cutting.There are two types of expanded polyethylene foams that can be machined with the same tools:

- Non-crosslinked: Non-crosslinked polyethylene foam for packaging is a polyethylene-based polyolefin. To obtain this polyethylene foam, a swelling gas, usually isobutane, is used. An expanded polyethylene is obtained without transforming the chemical structure of the polyethylene, thus facilitating its recyclability.

- Cross-linked: Cross-linked polyethylene foams are a polyethylene-based foamed plastic material.For foaming, either a chemical reaction is used with the help of catalysts, or the base of the product is exposed to radiation from high energy sources such as gamma rays.

Generally, a family of plastic foams or polyethylene foams is obtained, small and closed cell with good resistance to temperature and ultraviolet rays, but hardly recyclable.

BENEFITS OF MACHINED EXPANDED POLYETHYLENE FOAM

Machined foam has two major advantages:

- It does not require costly molds or tooling.

- It resistant to multi-impact, which guarantees its function in the event of repeated falls, making it ideal for ecommerce.

- It is recyclable and, depending on the raw material, it can be eco-friendly as it comes from sugar cane.

PROPERTIES OF MACHINED EXPANDED POLYETHYLENE FOAM

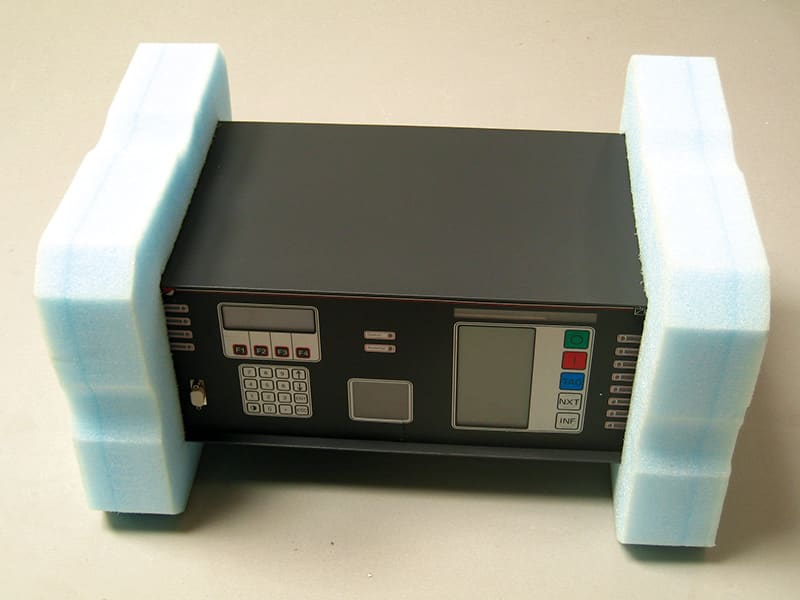

The main properties of non-crosslinked expanded polyethylene are its lightness, resistance to water, wear, aging and chemical agents.

As it is made of plastic material, it tolerates hand and machine manipulations. In addition, it maintains its resilience, strength and resistance to tearing and abrasion. It is extremely flexible, allowing for innovative designs.

Excellent performance in absorbing multiple impacts and vibration. Another of its qualities is that it has a very favorable environmental balance.

Colors: white, black and pink for antistatic.

Brafim has fine-grained non-crosslinked polyethylene materials. In addition to others whose origin is not from fossil raw materials but from sugar cane.

Cross-linked expanded polyethylene offers a wide range of colors and, being fine-grained, better abrasion resistance.

MACHINED EXPANDED POLYETHYLENE FOAM APPLICATIONS

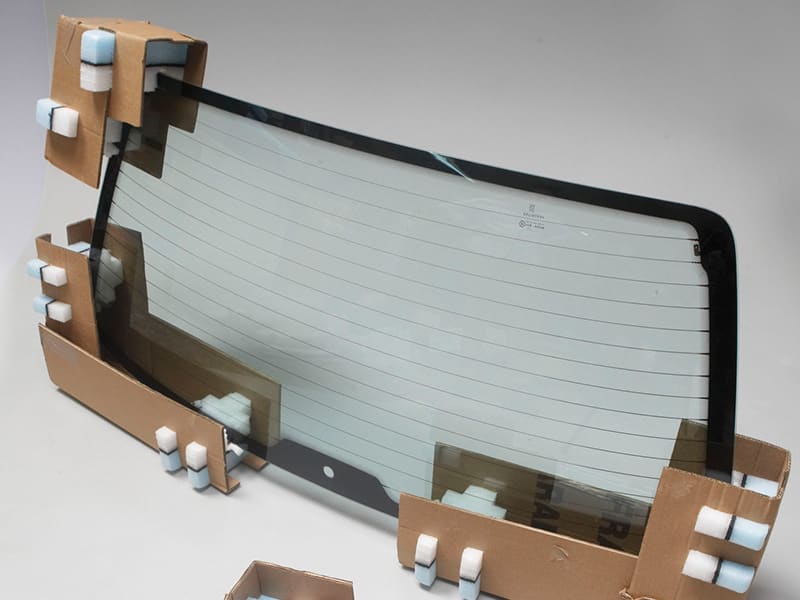

The versatility of polyethylene makes it the protection element par excellence. It can be used in all industrial sectors, from armament to art, from electro-medicine to luxury. Absolutely all industrial sectors.

Do you want to know the price of this product?

WE MAKE RESISTANT PACKAGING

We reduce incident rates

We optimize packaging costs

SAVE UP TO

48%

IN ALL YOUR COSTS

If you are interested in improving your packaging system

CONTACT US WITHOUT COMMITMENT

Formulario Dynamics 365 EN

"*" indicates required fields

Basic information on data protection

Responsible: BRAFIM MECPLAST, S.L.

Purposes : Manage the sending of information that you request. Sending commercial communications.

Legitimation: Consent. You can withdraw consent at any time.

Recipients: Your data will not be transferred to third parties except in case of legal obligation

Data subject's rights: To access, oppose, rectify and have their data deleted, as well as other rights as explained in the additional information.

You can access additional and extended information at this link.