Instapak: foam bags for packaging: BAGS STUFFED FOR PACKAGING

DESCRIPTION OF INSTAPAK, FOAM BAGS FOR PACKAGING

Instapak is a two-component foam from our partner Sealed Air. he foam expands inside a bag and before it sets, it adapts to the part to be packaged or to molds to produce ready-to-use molded parts when needed.

It can be packaged in a variety of ways:

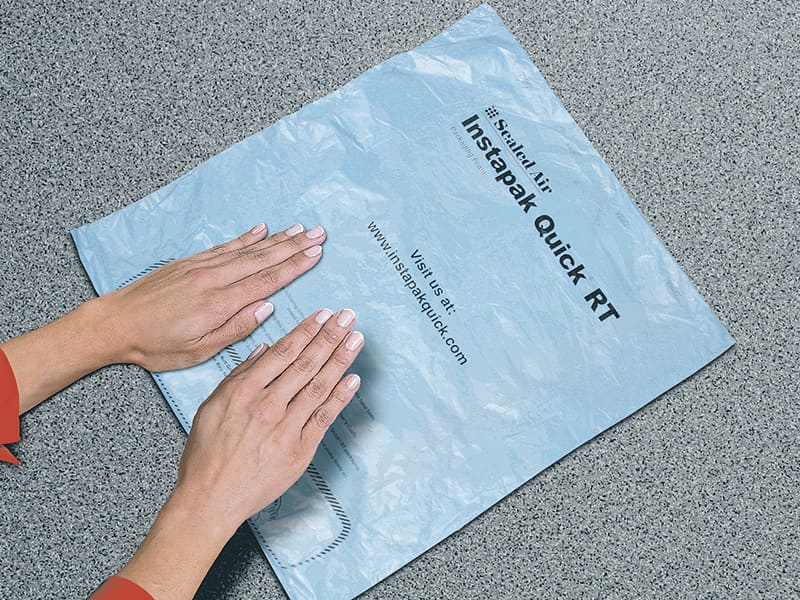

- Instapak Quick, is an on-demand protective packaging solution that can be used anywhere.After activation with a simple pressing or patting technique, the foam expands in seconds to form custom protective foam cushions. . Expanding up to 27 times its original size, Instapak® quick is ideal for saving space. No dispensing system or heating unit is required.

- Speedy packer Ideal for high volume packaging applications. The system quickly delivers superior, cost-effective product protection through agile programming that adjusts to the desired bag size. It also presents your product to your customers in an attractive, damage-free package.

- Instapak foamwrap, SEALED AIR® brand foam-on-demand packaging machine produces continuous foam-filled tubes. The SEALED AIR® brand Instapak® FoamWrap™ Express is a compact, bench-mounted foam packaging machine that produces continuous foam-filled tubes (CFT), which provide superior protection with minimal foam usage. The compact design, customizable programming and just-in-time accumulation capability make our Instapak FoamWrap Express system a perfect fit for any size packaging operation.

- SEALED AIR® brand foam molding systems produce custom-shaped Instapak® cushions. SEALED AIR® brand Instapak® foam molding systems produce cushions for products that require consistent, precise fit, custom-engineered protection. There is an Instapak® foam molding solution that fits every operation, regardless of volume, performance or configuration.

BENEFITS OF INSTAPAK, FOAM BAGS FOR PACKAGING

This solution offers the cost-saving benefits and proven performance of the Instapak foam portfolio.

- It provides custom fit, resilient cushioning, plus lightweight blocking and bracing for products of varying sizes and weights.

- Minimal space requirements.

- Can be manufactured both in-mold and in pre-determined sized, continuously produced bags.

PROPERTIES OF INSTAPAK, FOAM BAGS FOR PACKAGING

Polyurethane foam can be manufactured in different densities which will give it different cushioning behaviors depending on the product to be protected and its logistics.

APPLICATIONS OF INSTAPAK, FOAM BAGS FOR PACKAGING

- Ideal for short runs of fragile products

Do you want to know the price of this product?

Technical data of Instapak: foam bags for packaging, filled packaging bags

Instapack

| Code | Description | SIze of the flat bag | Bags per box |

| K501 | INSTAPACK QUICK RT N.10 | 38X46 | 135 |

| K502 | INSTAPACK QUICK RT N.20 | 46X46 | 96 |

| K503 | INSTAPACK QUICK RT N.60 | 46X61 | 78 |

| K504 | INSTAPACK QUICK RT N.80 | 51X76 | 54 |

WE MAKE RESISTANT PACKAGING

We reduce incident rates

We optimize packaging costs

SAVE UP TO

48%

IN ALL YOUR COSTS

If you are interested in improving your packaging system

CONTACT US WITHOUT COMMITMENT

Form Instapak: foam bags for packaging

Basic information on data protection

Responsible: BRAFIM MECPLAST, S.L.

Purposes : Manage the sending of information that you request. Sending commercial communications.

Legitimation: Consent. You can withdraw consent at any time.

Recipients: Your data will not be transferred to third parties except in case of legal obligation

Data subject's rights: To access, oppose, rectify and have their data deleted, as well as other rights as explained in the additional information.

You can access additional and extended information at this link.